| |

A GC Master (Glatt Coater) enables tablets and pellets to be

coated uniformly and reproducibly. The shortest possible process times can be

achieved due to the fully perforated drum.

Batch sizes from 100kg to 1500kg/batch.

|

| |

|

GC Master: Film- and sugar coating at the highest stage.

Gentle product handling

The main advantage is the gentle mixing and coating of tablets due to the

geometry of the drum and the Fischer mixing blades specially developed by Glatt.

These ensure absolutely homogeneous mixing with minimum stress on the product.

(-> Drum Coating)

|

| |

|

| |

Extremely flexible

The GC Master is adapted exactly to your requirements.

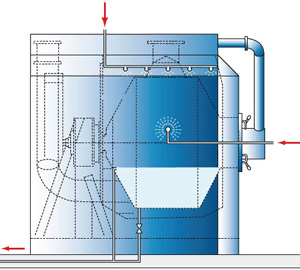

With WIP systems you can choose between simple pre-cleaning, or - with the

specific arrangement of cleaning nozzles - for a defined cleaning result of the

complete GC Master process area. This reduces manual cleaning as well as

cleaning times. |

| |

Principle of WIP cleaning |

|

|

|

Best possible product quality

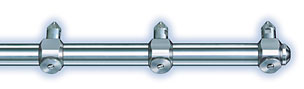

Efficient film coating using the exclusive Glatt GCSD high performance nozzle

with ABC-cap:

-No beard formation

-Excellent spray pattern

-Adjustable spray angle

An intelligent and extremely compact construction:

-Nozzle maintenance possible within only a few minutes and without any tools

-Suitable for aqueous and organic processes

-Sugar coating optional Smart product discharging

|

| |

High performance nozzle GCSD |

|

| |

Glatt single material sugar coating nozzle

The GC Master is also particularly suitable for Sugar Coating. Both in

conventional design with sugar inlet rakes and with the special single-material

sugar nozzle, especially developed by Glatt for optimum distribution and

shortest process times. |

Single material sugar coating nozzle |

|

Simple handling

-Easy and smooth-running operation of the spray arm

-Thanks to optimized design, excellent cleaning capability and outstanding

inspection facilities of the whole process area

-Feed and discharge is possible both in open and in enclosed design (-> Total Containment)

|

Product discharge |

|

| |