|

|

|

|

|

|

Homogeneous granules.

Gentle product handling.

Intensive mixing of the solid material.

Uniform spraying of all particles in the fluid bed.

Uniform, reproducible product quality.

|

| |

| |

Process advantages

Fluid bed granules are very homogeneous. All particles in the powder mix are

sprayed evenly with liquid starting materials. The type of granulate (size,

density, porosity) can be influenced over a wide range by the adjustment of

various parameters.

|

|

|

|

Principles of operation

Glatt implements this process with different capacities according to the

process requirements, starting materials and the required product

parameters.

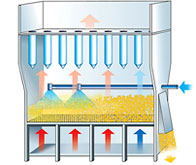

Batch Fluid Bed Systems

with batch sizes from 20g to 1.5t/batch.

Continuous Fluid Bed Systems with

throughputs from 20kg to 5t/h.

Depending on the process requirements, the liquid starting material is

usually sprayed in from above or, in individual cases, from the bottom (Top

Spray or Bottom Spray granulation respectively).

Batch fluid bed

For Agglomeration/Granulation in batch

mode, the dry starting product is placed in the product container. Here it is

mixed vigorously in the heated gas stream, held in suspension and

agglomerated/granulated by spraying with a suitable bonding material. The

product is then dried to the required end moisture content with high heat and

material transition coefficients.

|

| |

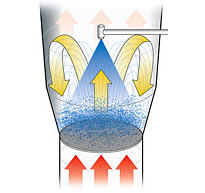

Principle:

Principle:

Batch fluid bed granulation, Top Spray |

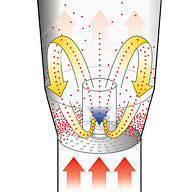

Principle:

Principle:

Batch fluid bed granulation, Bottom Spray

|

|

|

|

Continuous fluid bed

Continuous granulators are sub-divided into several granulation zones, which

are operated at different speeds and temperatures, e.g. Agglomeration/Granulation in the first and second

sections, drying in the third and cooling at the end of the process chamber.

|

| |

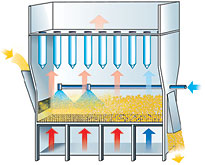

Principle:

Principle:

continuous fluid bed granulation in the Glatt fluid bed (GF)

Top Spray |

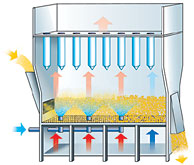

Principle:

Principle:

continuous fluid bed granulation in the Glatt fluid bed (GF)

bottom Spray

|

|

| |

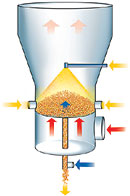

When granules are to be manufactured from liquid starting materials, the

particles are not agglomerated in the fluid bed but repeatedly re-coated until

the required grain size is achieved

(-> Spray Granulation).

In the batch process,

the undersized grains from the previous batch are used as the starting material.

In the continuous process, the undersized grains are continuously separated from

the product and continuously fed back into the process as germ material.

|

| |

|

|

Principle:

continuous spray granulation

in the Glatt fluid bed (GF)

Top Spray |

Principle:

continuous spray granulation

in the Glatt fluid bed

(AGT) |

|