| |

Coating or encapsulation of particles by melting.

|

| |

|

Particle and pellet coating, micro coating, flavour encapsulation.

|

Effective process.

Fast coating.

No evaporation of solvents

required.

|

Product advantages.

Protection against moisture.

Delayed release of

active ingredients in the case of pharmaceutical drugs.

Taste masking.

|

| |

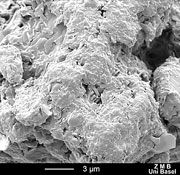

Uniform and dense coatings.

Low to high coating masses in comparison

with the particle to be coated.

|

| |

Coating thickness.

Between ca. 25µm and

several hundred µm.

|

| |

Process Principles

|

|

| |

|

| |

A very even application of the coating material is an important feature of

the coating process. Coatings must be dense and without mechanical damage and

cracks. Lipid/Hot melt coating is a very effective process for the application

of waxes and molten materials as protective films for manipulating the particle

properties.

Glatt offers Fluid Bed Coating (Top

Spray Coating, Bottom Spray Coating, Rotor Coating) as a technical solution for

coating different particles and tablets. For particles difficult to fluidize we

have developed the Glatt Spouted Bed

Technology.

The coating fluid is sprayed onto solid materials, which are

presented to it. The introduction of process air causes the film coating to

solidify. Small droplets and a low viscosity ensure that the distribution is

uniform.

The time and energy-intensive evaporation of solvents can be

dispensed with by the use of molten materials as coating liquids.

|

| |

Specific manipulation of the product characteristics of particles or tablets

such as:

|

|

Shelf life

Hygroscopicity

Flowability

Surface structure

Solubility

Release of active ingredients

Taste

Smell

Behaviour when dissolving

Sensitivity to light

Visual attractiveness

|

2-layer coating on micro pellets

|

|

| |

Manufacturing options

Glatt provides systems with different capacities:

Batch Fluid Bed Systems

with batch sizes

- from 2g to 1500kg/batch (Top Spray Coating)

- from 50g to 700kg/batch (Bottom Spray

Coating)

- from 500g to 250kg/batch (Rotor Coating)

Continuous Fluid Bed Systems with

throughputs from 20kg to 5t/h

Spouted Bed Systems with throughputs

from 200g to 3t/h. |

| |

|

|